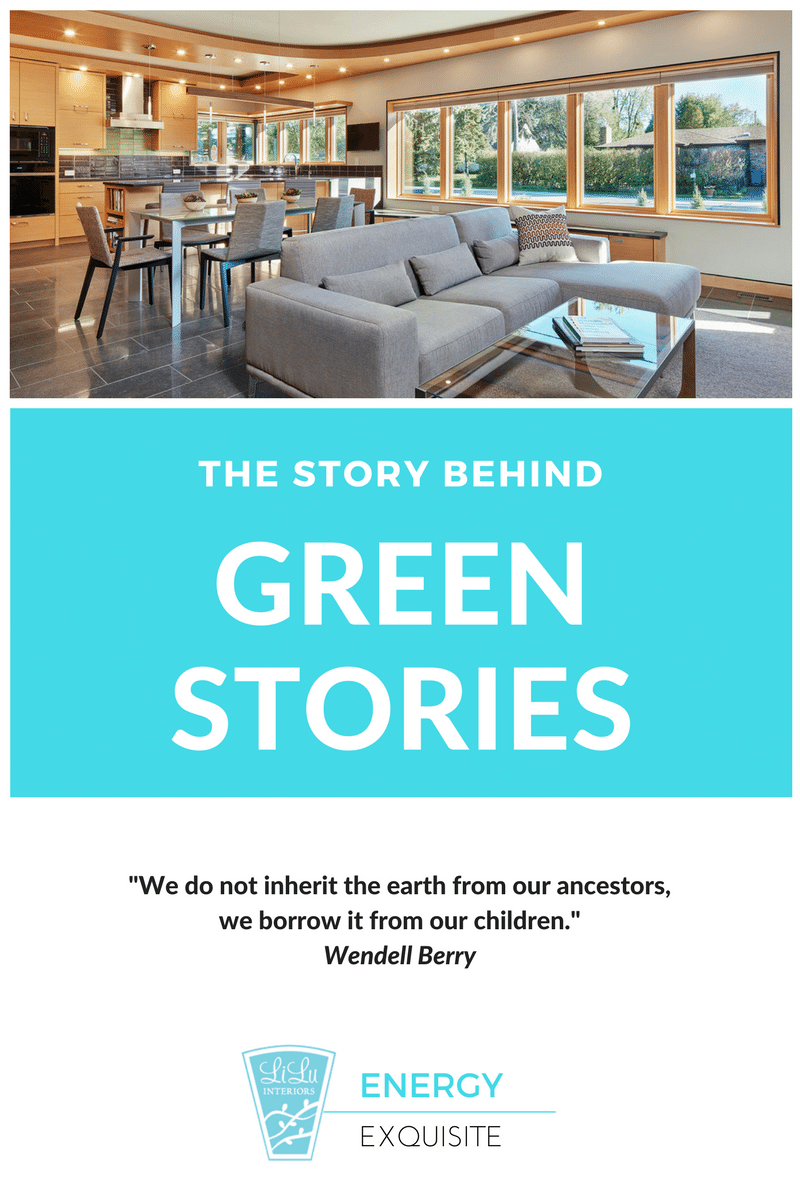

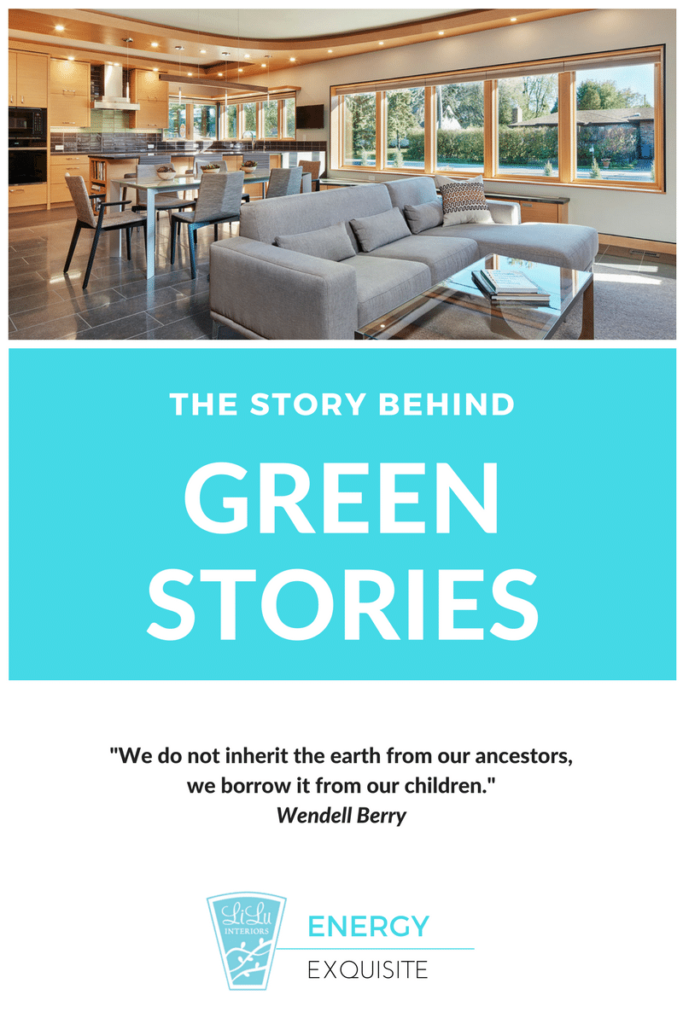

The Story Behind Green Design Stories—Friday’s Look of the Day

Did you know that sustainable and energy efficient materials all come with a green design story? And by knowing more about a material—everything from manufacturing to lifecycle—homeowners can make more informed decisions. “We would not have been able to keep up with the research alone,” Mark said. “LiLu not only found the materials, but they also presented us with several options for each based on if their story matched up with our requirements.

No detail was too small as we worked with our clients Mark and Kate to balance efficiency with aesthetic, making sure every fixture, finish, and fabric was equally representative of both. Here are the green stories for just a few selections from LiLu’s most recent project Energy Exquisite, which is now published in our portfolio.

Pennsylvania Bluestone Tile

WHY it was chosen?

Made in the USA

At least 20% Pre-Consumer Recycled materials Green Squared Certified:

It is the first manufacturer to earn TCNA”s Green Squared Certification Evaluates products and processes in 5 key environmental and social categories including:

Product characteristics

Manufacturing operations

Corporate governance

Innovation

End-of-life product management

Durability and Easy Maintenance:

Cross-sheen finish is integrated into tile to protect the tile from the damaging, defacing effects of scuffs, stains, even permanent marker allows them to be easily removed Smooth, non-glare and non-slip floor for aging in place Warm and cool gray tones create an overall backdrop for the home

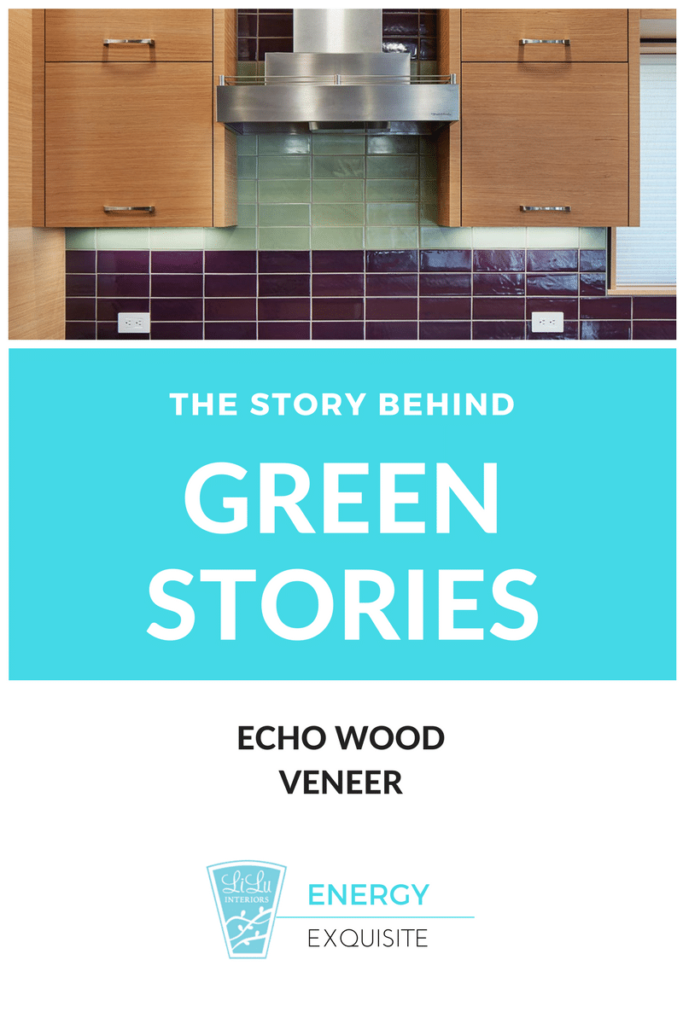

Echo Wood Veneer

WHY it was chosen?

FSC Certified

Meets or exceeds the California Air Resources Board Standard for Formaldehyde emissions Defect-free panels offer maximum yield and minimize waste Only water-based dyes are used containing no harmful heavy metals 100% of the harvested wood fiber is used in the production of Echo Wood The use of Echo Wood preserves rare and exotic trees for future generations A horizontal line is present throughout the house, the grain continues this theme throughout

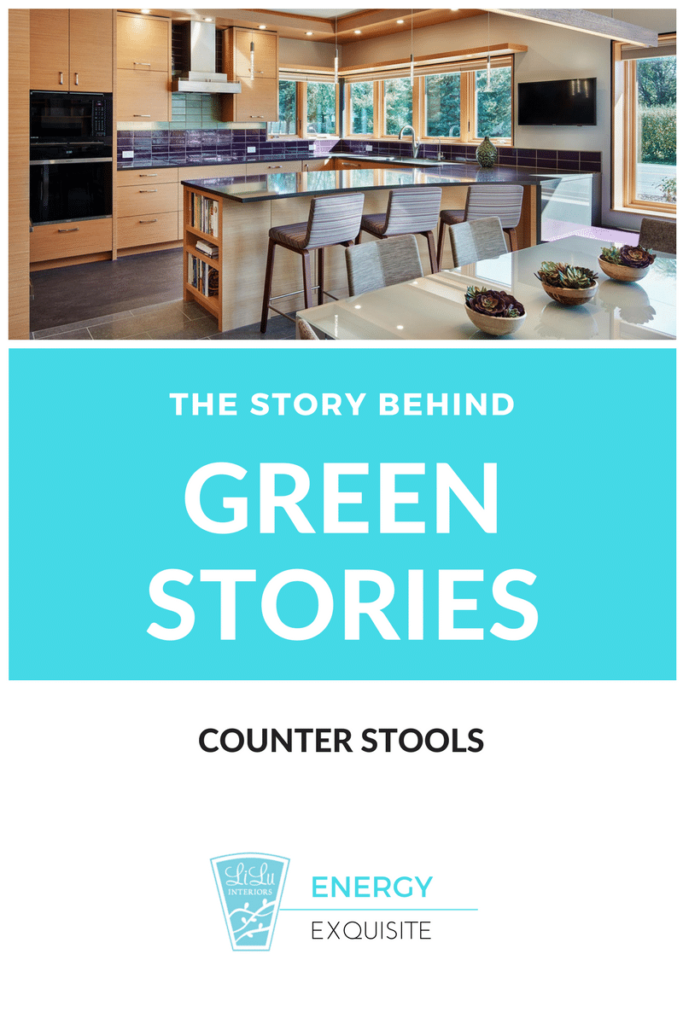

Counter Stools

WHY we chose them?

This company has implemented environmental management systems in its manufacturing processes and they operate in accordance with all major international standards and certifications of compliance and environmental care for its products (ISO 9001, ISO 14001 British Standards; BIFMA, FSC®, PEFC). These standards and certifications are the ultimate guarantee of the sustainable, durable and quality chairs and tables that are produced The curved back of the stool mimics the curvature in the soffit above and the countertop.

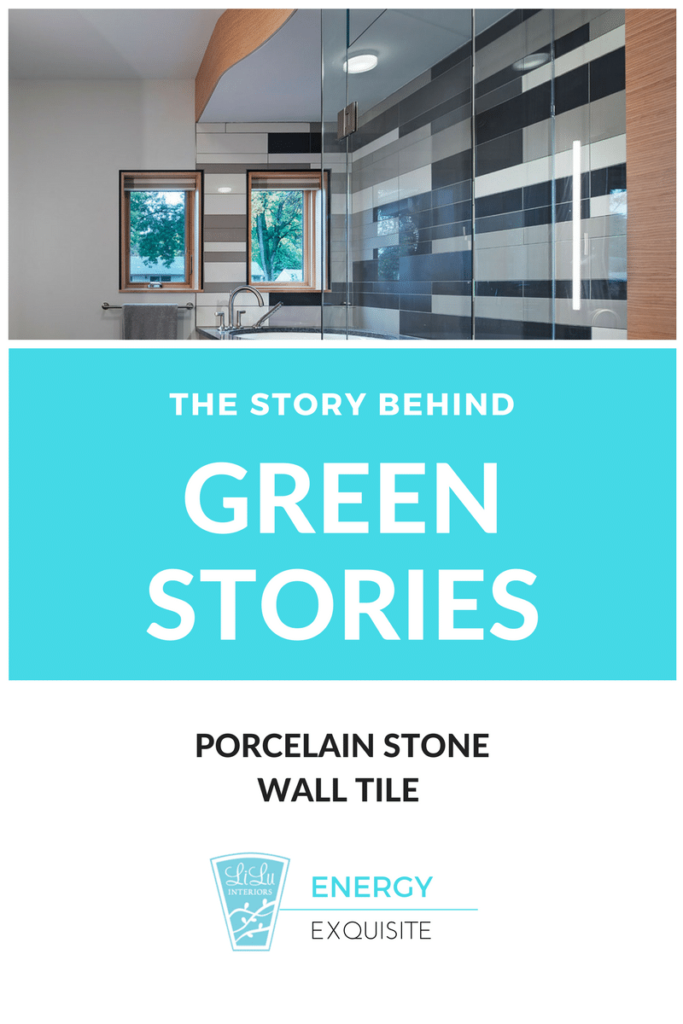

Porcelain Stone Wall Tiles

WHY was it chosen?

Made in the USA

At least 20% Pre-Consumer Recycled materials Green Squared Certified:

Crossville is the first manufacturer to earn TCNA”s Green Squared Certification Evaluates products and processes in 5 key environmental and social categories Product characteristics Manufacturing operations Corporate governance Innovation End-of-life product management Durability and Easy Maintenance:

Cross-Sheen finish is integrated into tile to protect the tile from the damaging, defacing effects of scuffs, stains, even permanent marker and allows them to be easily removed

Cabinet Knobs

WHY was it chosen?

Recycled Glass

The company utilizes sustainable and socially responsible business practices

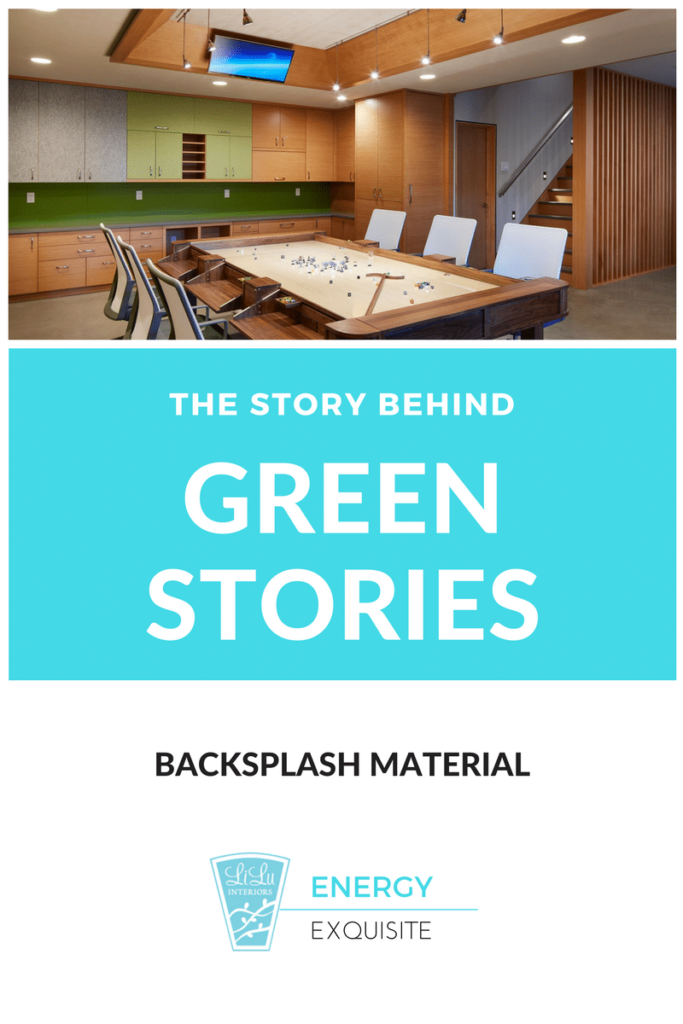

Backsplash Material

WHY it was chosen?

100% Recycled

Maintenance Free

Durable

No VOC off Gassing

Contributes to LEED Points

Vibrant color adds to the asymmetry

This company offers a line of post consumer recycled high density polyethylene panels (HDPE) in a variety of colors. Made with 100% plastic that has been discarded and recovered from the waste stream, the panels boast 8 recycled milk jugs per pound.

The plastic can be used in an array of applications where high durability and no maintenance are desired in both wet and dry applications, indoor or outdoor.

The recycled plastic comes in 4 x 8 panels and is nearly 100% second generation recycled material that has the appearance and characteristics of virgin material. Virgin HDPE has been used and proven as a preferred material in several market segments, and there is no application where this recycled HDPE cannot replace virgin material.

VIEW THE COMPLETED PROJECT